YAST-FD330T is a one of paper box bag with handle making machine series.

Fully automatic square bottom paper bag machine is designed for the production of paper bag with twisted handles. This is multi-function machine, you can produce bags with handles or without handles. It’s widely used.

Advantages:

1.Excellent durability

This machine constructed with quality parts for excellent durability and accuracy assurance.

2.Highly economical

Easy operation and work with few operators, using less electrical power consumption and sub material .

3.High productivity

Suitable for big and small batch production and reduced adjustment time and improved production efficiency. Safety has been ensured. While improve the production efficiency, it pays more attention to safety, adopts safety covers and emergency switches to avoid accident.

4.High security

While improving the production efficiency, safety has been improved as well.

Product instruction

YAST-FD330T is suitable for mass production of shopping bags in industries such as food and clothing. The on-line process consists of twisted handles making from paper rolls and twisted rope, delivery of handles to paste unit, re-cutting of paper on position of rope, patch position gluing, handle pasting, and paper bag making.

Product Parameter(specification)

|

Model |

YAST-FD450T |

YAST-FD330T |

YAST-FD450BT |

|

Cutting length |

270-530mm |

270-530mm |

380-760mm |

|

Cutting length (handle) |

270-430mm |

270-430mm |

380-660mm |

|

paper bag width |

210-450mm |

120-330mm |

210-450mm |

|

Paper bag width (handle) |

240-450mm |

200-330mm |

240-450mm |

|

paper bottom width |

90-180mm |

60-180mm |

100-220mm |

|

paper thickness |

60-150g/m |

80-150g/m2 |

80-150g/m |

|

paper thickness (handle) |

80-150g/ |

80-150g/m2 |

80-150g/ |

|

Machine speed |

30-180pcs/min |

30-200pcs/min |

30-150pcs/min |

|

Production speed without handle |

30-150pcs/min |

30-180pcs/min |

30-120pcs/min |

|

Production speed with handle |

30-130pcs/min |

30-150pcs/min |

30-130pcs/min |

|

Paper roll width |

590-1290mm |

380-1050mm |

630-1370mm |

|

paper roll width (handle) |

670-1290mm |

620-1050mm |

710-1370mm |

|

Handle rope height |

100-120mm |

100-120mm |

100-120mm |

|

Handle distance |

72/85mm |

72mm |

75/85mm |

|

Patch length |

190mm |

152mm |

190mm |

|

Patch width |

50mm |

50mm |

50mm |

|

Patch paper thickness |

100-135g/m2 |

100-135g/m2 |

100-135g/m2 |

|

Paper paper diameter |

Φ3-5mm |

Φ3-5mm |

Φ3-5mm |

|

Patch paper roll width |

90-100mm |

90-100mm |

90-100mm |

|

Roll paper diameter |

∅1300mm |

∅1300mm |

∅1300mm |

|

Inner diameter of paper |

∅76mm |

∅76mm |

∅76mm |

|

Machine power |

380V 2Phase 4 lines 41.5kw |

380V 2Phase 4 lines 41.5kw |

380V 2Phase 4 lines 41.5kw |

|

Machine weight |

15500kg |

15000kg |

16500kg |

|

Machine size |

14000*6000*2400mm |

14000*6000*2400mm |

14000*6500*2400mm |

Main features

1.Use France SCHNEIDER touch screen human-computer interface, making the machine easy to operate and control.

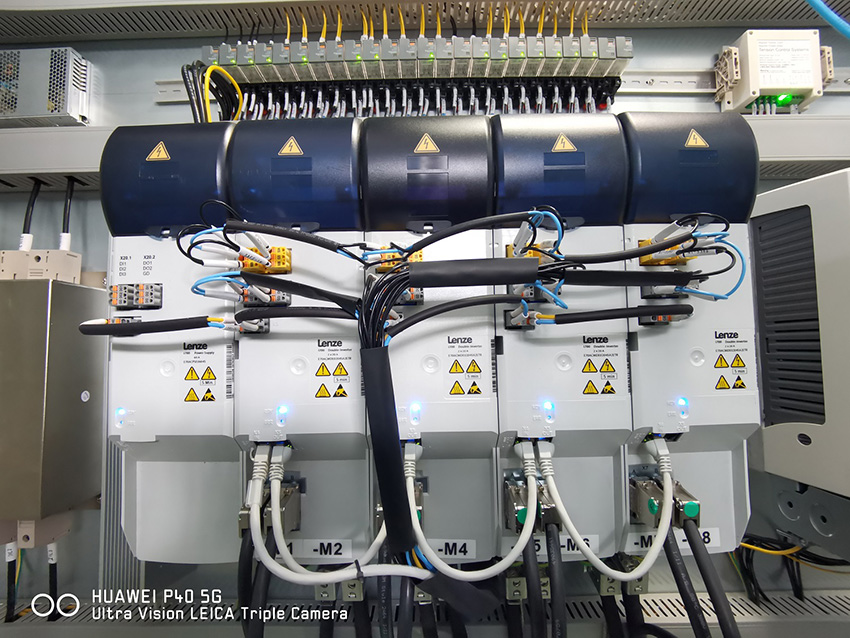

2.Adopt Germany original LENZE PC control, integrated with optical fiber. Thus ensure stable and high speed running.

3.Adopt Germany original LENZE servo motor and German original SICK photoelectric eye correction, tracking printing bag accurately.

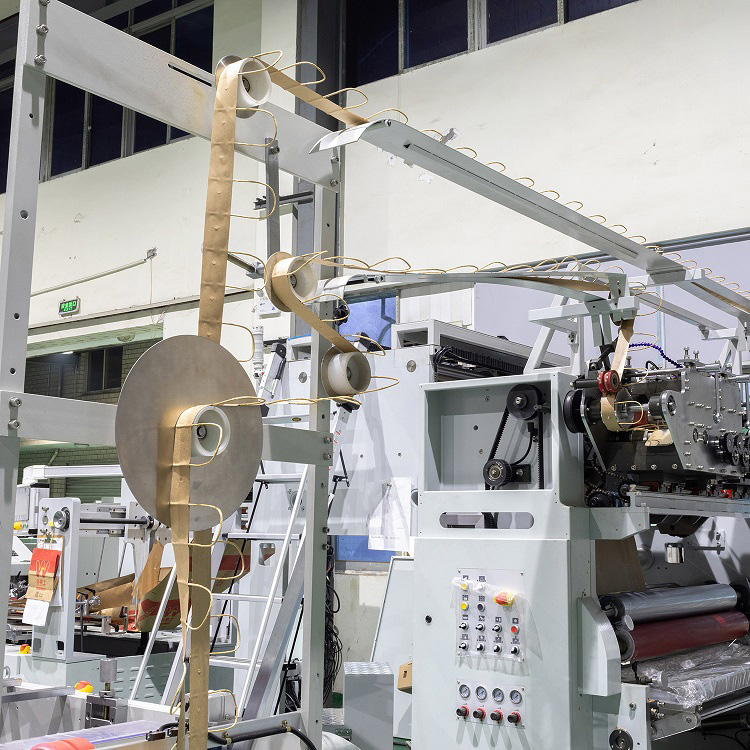

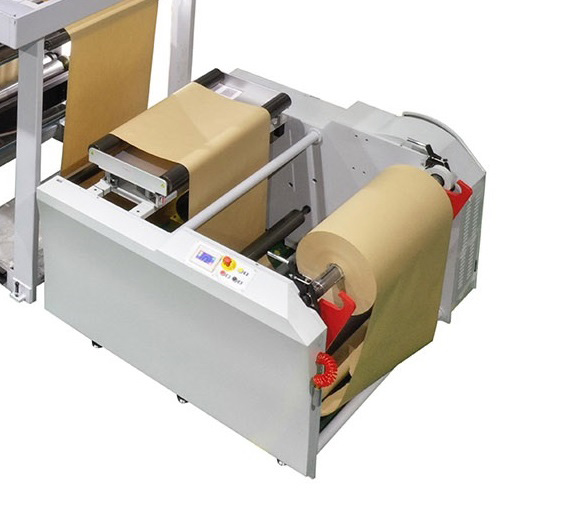

4.Raw material loading adopts hydraulic auto-lifting structure. Unwinding unit adopts auto tension control.

5.Raw material unwinding EPC adopts Italy SELECTRA, reducing material alignment time.

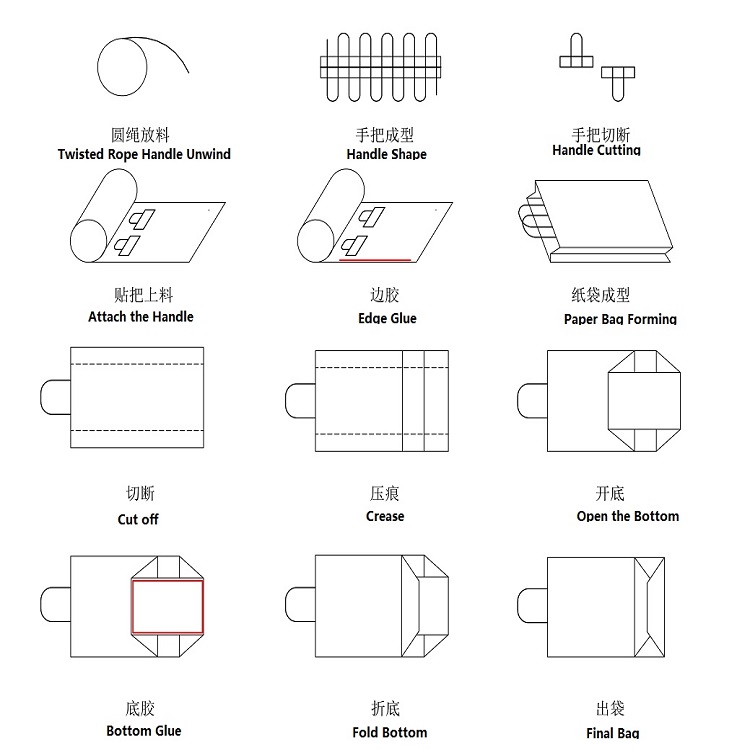

The flow chart

Machine details

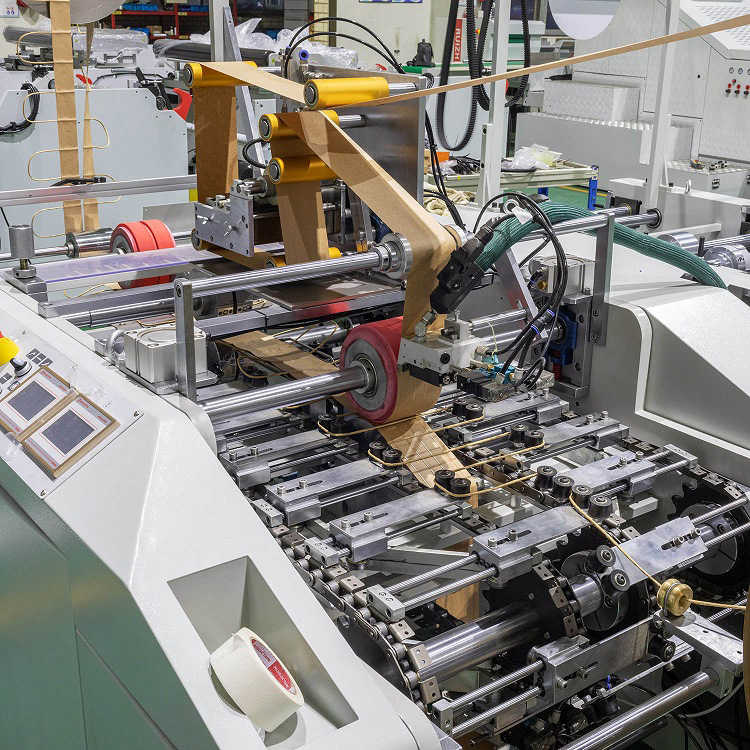

This machine puts a handle rope between two pieces of paper and fixes it together with hot melt glue as a hand grip. The handle material can be twisted paper rope, twisted p.p.rope, acrylic resin rope,etc.The handle making machine is installed parallel to the main machine. It’s possible to install it on either side of the main machine that according to the space.

The handle making machine is installed parallel to the main machine. It’s possible to install it on either side of the main machine that according to the space.

Rolling inflatable shaft: easy to use, adopt automatic Hydraulic cylinder, make it automatic to load the roll up and down, just by pressing the button to start the cylinder. Help you out of any carry job.

The molding handle is automatically sent to the paper roll for pasting.After the handle is attached to the paper roll, the bag is folded into shape.

The automatic counting function can be set, and the counting is accurate.Reach the set number will naturally be higher than the other bag prompts you.

Using German Rolex system, good stability, faster speed, high power, up to 120 meters per minute。.

Shipping package

We offer wrapping film out side and fumigation wood plant .

Deliver and serving

1.Q:What about your main market?

A: Our products be sold well in 30 provinces and have good reputation in China, also we pay attention on developing the overseas market, such as Europe, Russia, Southeast Asia, Middle and South America, Africa, and other countries.

2.Q:How does your factory do regarding quality control?

A: Quality is the most important principle. Our group always attach great importance to quality controlling from the very beginning to the very end. Our factory has passed ISO and CE certification.

3.Q: What information should I let you know if I want to get a quotation?

A: First, Paper raw material: Reel paper or Sheet Paper. Second, sizes of the paper bag, thickness of paper. Send sample bag picture if available Then we will recommend the right machine to you!

4.Q:How about machine testing?

A:You can visit us, we will test the machine with you together. If you can’t come, we also can send videos of machine running to you for your reference.

5.Q:What about warranty and do the engineers available to overseas?

A:The technicians can go for installation after all the utilities are ready like electricity and air. All our expenses including visa fee, round tickets and accommodation are paid by you and salary is USD 100 per day.

We offer a 12-month warranty. During the warranty period, we provide free replacement of damaged parts due to quality problems. All failures caused by improper use of the buyer (including unauthorized modification of PC and touch screen built-in software) are not within the scope of the warranty (except for the vulnerable parts of wearing parts).

GET A QUOTE